6+ Weld Line Injection Molding

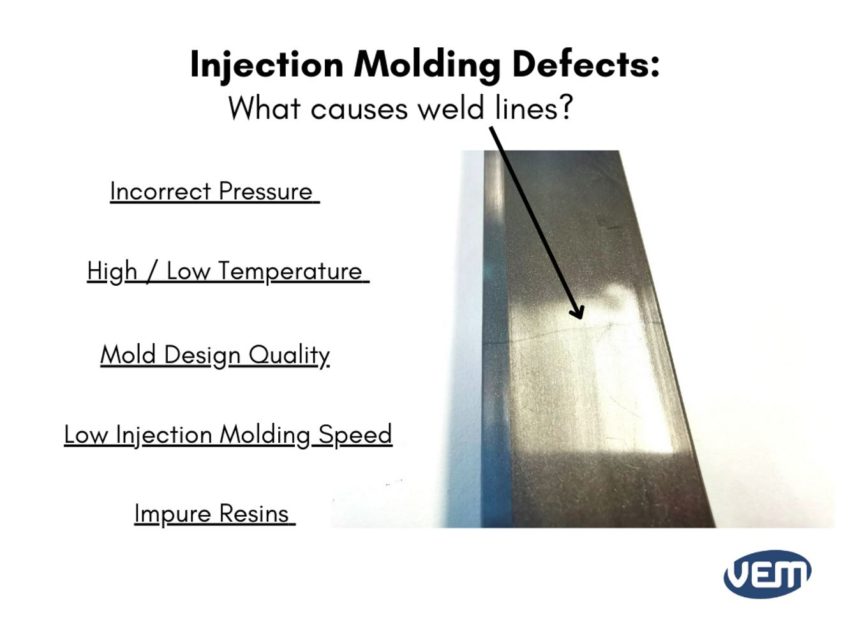

1 Increase the injection pressure and prolong the injection time. High speed allows the melt to reach the.

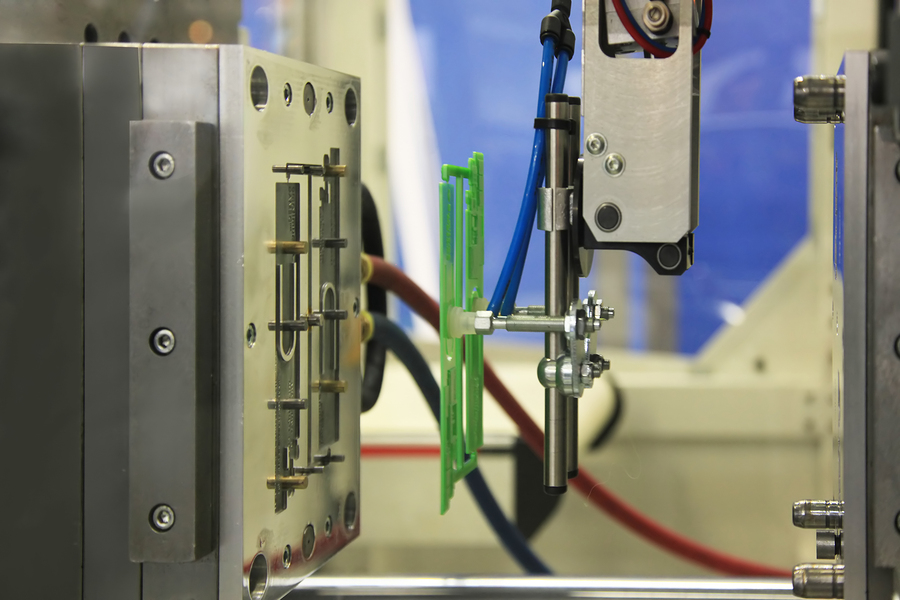

More Gloss Fewer Weld Lines With Variothermal Molding Plastics Technology

2Double push filling method.

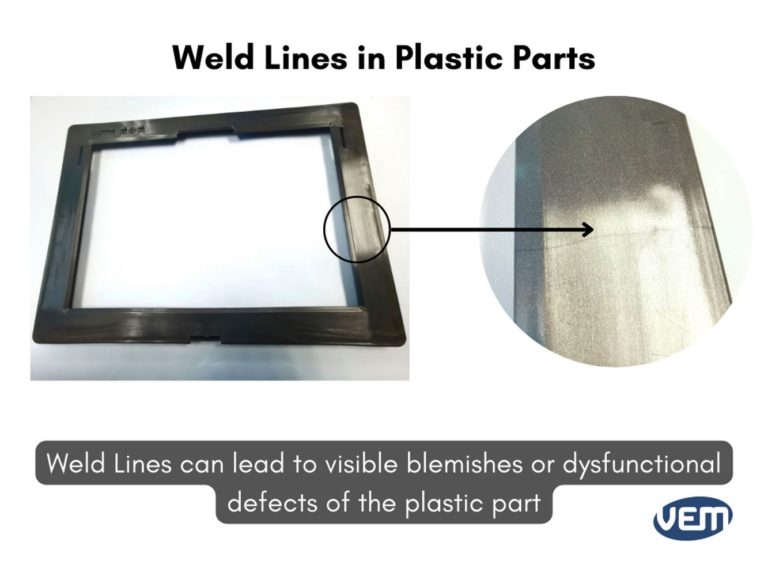

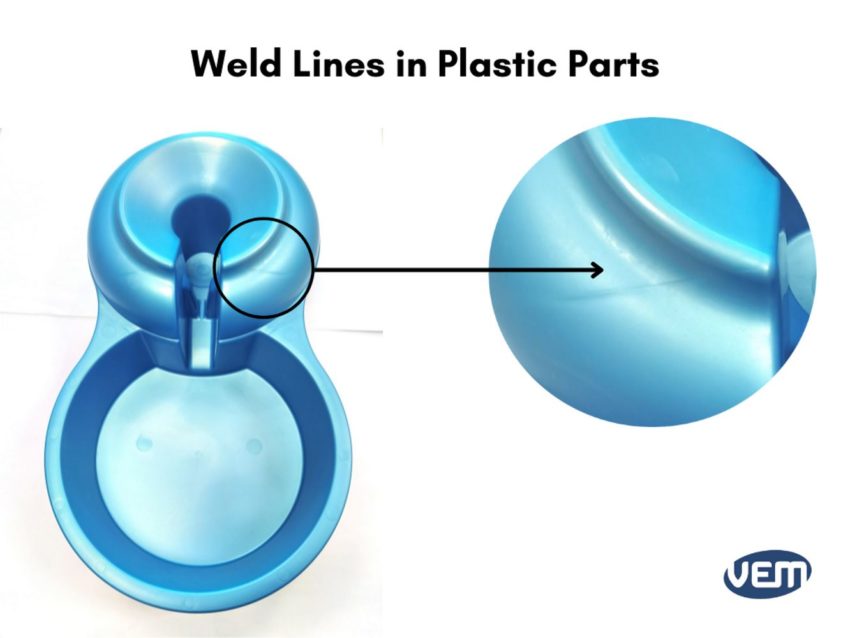

. Weld lines lead to two significant issues with an injection molded product. 2 Adjust the injection speed. They occur when melt flow fronts collide in a mold cavity.

Less than 3mm mold temperature use 50 -70 Celsius degrees 3-6mm mold temperature use 70-90 Celsius degrees 6-10mm. 1Vibration assisted injection molding. The possibilities of preventing the weld lines creation or reducing the negative effects of their occurrence have been presented eg by changing the construction and location.

Moldex3D Webinar2020Solving Weld Line and Air Traps Through SimulationIntroTwo common cosmetic surface defects that often occur are weld line and air tra. In this study epoxy molding compounds EMC filled with glass beads were fabricated with a twin-screw-extruder TSE and tempered before further processing to. An automatic-search multiple-regression analysis for optimum factors was applied in order to generalize the test resultsThe results are summarized as follows1 It became clear that weld.

1 Increase the injection time and reduce the injection speed 2reduce the barrel temperature and nozzle temperature. To investigate the effect of hot gas heating in injection molding on the weld line appearance an experiment was conducted with the molding parameters listed in Table 2. The first is that they deform the parts surface by leaving unsightly lines that the consumer may not want.

⑥Appropriately increase back pressure and adjust screw speed so as to ensure a uniform melt temperature. In injection molded parts there are 2 types of weld. Weld or knit lines are perhaps the most common and difficult injection molding defect to eliminate.

When referring to injection molded parts the phrase parting line refers to a line on the part that is created where the two halves of the mold come together. 3Sequential valve gate technology. The thickness of product temperature of mold.

⑤Reduce clamping force to ensure good ventilation. What results is a. If the plasticizing ability of the plastics injection molding machine is insufficient the plastic cannot be fully.

If a vent is not well set in the weld line of plastic products to exhaust gas the appearance and strength of. A poor knit line. Plastic Injection Molding Process.

4The utility model relates to a mold structure capable of eliminating the. Set the machine of the appropriate size process. Weld lines are formed when there is an inability of two or more flow fronts to knit or weld together during the molding process.

WELDLINE TROUBLESHOOTING INJECTIONMOLDINGstudy more. Insufficient plasticizing ability of injection molding machine. The weld mark is the confluence point of the resins or the end of the resin flow.

Molding Defects Weld Lines

Injection Molding Weld Line Plastopia

Weld Lines Plastic Injection Molding Defects Ecomolding Com

Weld Line In Injection Molding Cuase How To Troubleshoot Fow Mould

Molding Defects Weld Lines

Schematic Diagram Of A Weld Line Formation And Its Welding Angle Download Scientific Diagram

Weld Lines Defects In Plastic Injection Molding Process

Scielo Brasil Welding Lines Formation In Holes Obtained By Low Pressure Injection Molding Of Ceramic Parts Welding Lines Formation In Holes Obtained By Low Pressure Injection Molding Of Ceramic Parts

Scielo Brasil Welding Lines Formation In Holes Obtained By Low Pressure Injection Molding Of Ceramic Parts Welding Lines Formation In Holes Obtained By Low Pressure Injection Molding Of Ceramic Parts

Weld Knit Flow And Meld Lines Plastics Design Advice For Injection Molding Cosmetic Quality

How To Solve Weld Line In Injection Molding Trouble Shooting

Weld Line Defect Analysis And Troubleshooting Fluent Co Ltd

Weld Line Defect Analysis And Troubleshooting Fluent Co Ltd

Weld Line In Injection Molding Cause Troubleshooting Mechanicaleng Blog

Pdf The Examination Of Weld Line Properties In Injection Molded Pp Composites

Solution For Weld Line Of Injection Products Gud Mould

Molding Defects Weld Lines